However, encountering a fault can be a very frustrating experience.

Conclusionįaulting a PLC isn’t an easy task. The user may press the “Clear Majors” button in order to reset the fault. The description of the fault will generally indicate the area of the program where the fault happened, the nature of the fault, as well as the date and time of it, ‘s last occurrence. As mentioned previously, we’ve caused a major fault & thus it will be listed within the “Major Faults” tab. By entering the PLC menu, the user will be able to navigate into the “Major Faults” and “Minor Faults” tabs which will list all the current faults on the controller.

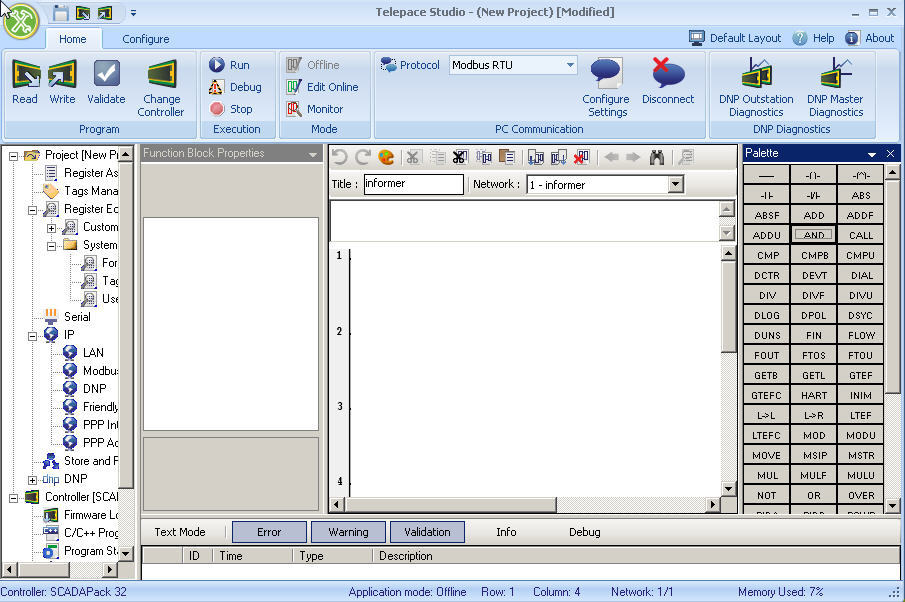

Once the PLC is faulted, it’s possible to get more information about the nature of the fault. You may either change the index range within the FOR loop or increase the size of the array which is being called by this variable. The only solution is to fix the problem we’ve created in the software. However, as soon as you change it back to “Run”, the same logic will execute and fault out the PLC once again. The PLC will enter into a “Program” state. In this state, you may choose to attempt a PLC reset. Here’s an implementation of the FOR loop instruction which will cycle from 0 to 30 with a step size of 1 through the routine “_06_FORloop”. We often use it in our alarm & fault arrays as well as tag definitions & aliasing. It allows the user to cycle through multiple iterations of a program with a single rung. The FOR loop is an extremely useful instruction.

Building a FOR Loop Instruction in Ladder Logic There are many ways to create this scenario, but we did want to demonstrate the flaw within the FOR Loop instruction especially due to the fact that this has occurred within our organization recently. We will be exploring one of these conditions which are created by calling an element within an array which is undefined.ĭo note that the fault which we will be creating is common to other languages & isn’t something which you should expect only on a PLC. However, poor programming may cause a PLC to enter an undesired state which brings the entire system down and bring manufacturing to a halt. There are many ways to fault out a PLC, but they are generally extremely reliable and operate without a problem. Although it’s not encouraged to introduce conditions which may result in faults, this is something which can be practiced and observed within a test environment. Knowing how to deal with PLC faults within an industrial environment is an invaluable skill.

0 kommentar(er)

0 kommentar(er)